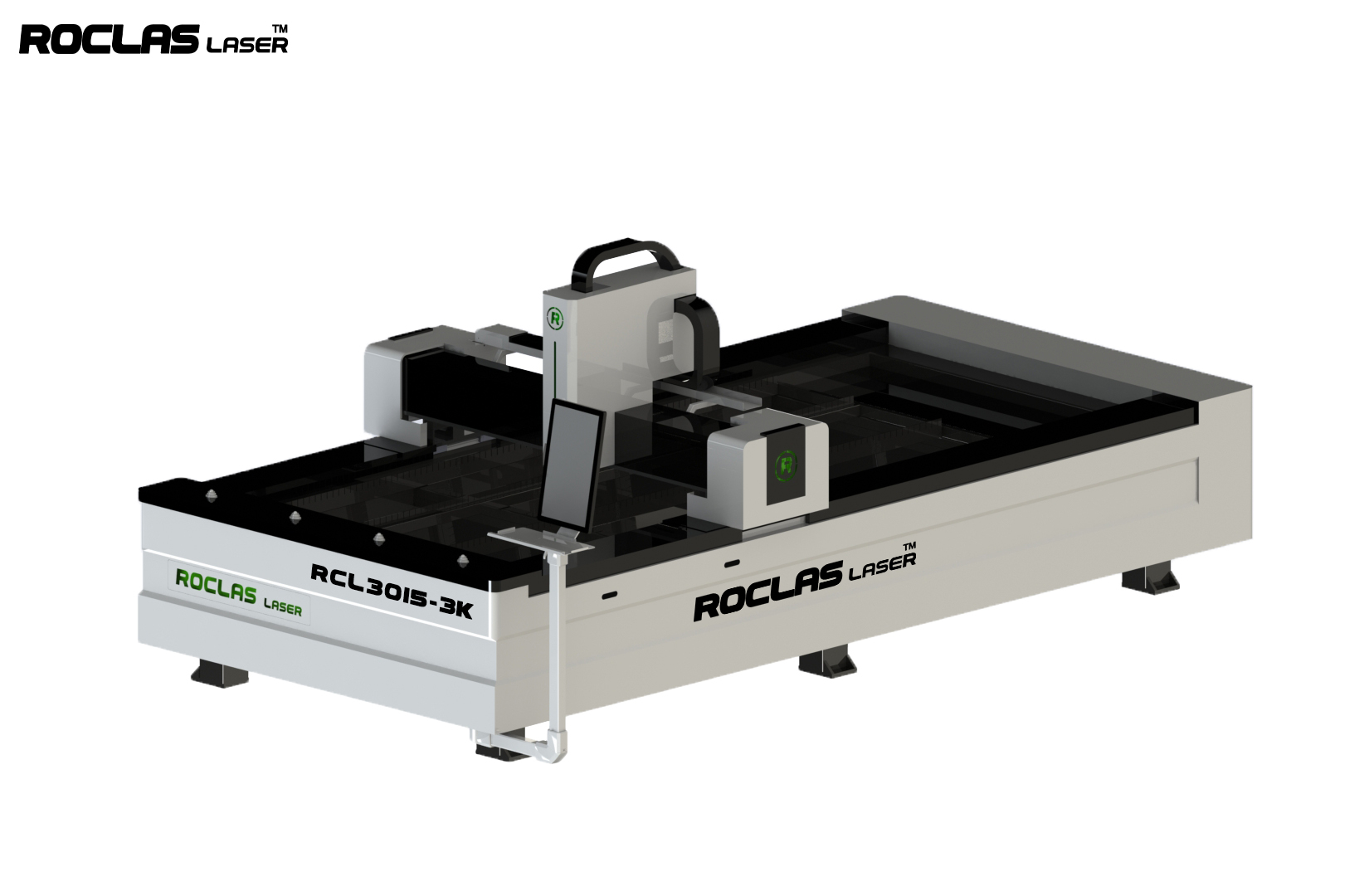

The Technology That Delivers 0.01mm Accuracy in ROCLAS Laser Cutting Systems

In the competitive world of industrial laser cutting, ROCLAS Fiber Laser Cutting Machine stands out with its remarkable 0.01mm processing accuracy - a benchmark that redefines precision standards. This extraordinary capability isn't achieved by chance but through meticulously engineered solutions at every level of the machine's construction.

At the heart of ROCLAS' precision lies its robust mechanical architecture. The machine features a high-strength steel tube structure that undergoes rigorous tempering and stress-relieving processes. This treatment ensures exceptional bed stability even during high-speed operations, effectively minimizing vibrations that could compromise cutting accuracy. When combined with the machine's advanced vibration damping system, this design creates a rigid foundation for maintaining micrometer-level precision across different cutting conditions.

The movement system represents another critical factor in achieving 0.01mm accuracy. ROCLAS employs imported high-precision linear guides and ball screws known for their minimal friction coefficients. These components work in perfect synchronization to ensure smooth, consistent motion during rapid acceleration and deceleration cycles. The dual-drive system further enhances positional repeatability, allowing the cutting head to return to exact coordinates repeatedly without cumulative errors.

Optical components play an equally vital role in maintaining extreme precision. The fiber laser beam path is carefully optimized to minimize divergence, ensuring consistent energy density at the cutting point regardless of the workpiece's position. This optical stability, when paired with the machine's real-time focus control system, guarantees uniform cut quality across the entire working area.

ROCLAS' intelligent control system acts as the brain behind this precision. Advanced algorithms continuously monitor and adjust parameters such as beam power, cutting speed, and gas pressure in response to material variations and environmental conditions. This adaptive capability ensures that the 0.01mm accuracy standard is maintained whether processing thin sheets or thick plates, in different ambient temperatures or humidity levels.

Maintaining such high precision requires equally rigorous calibration protocols. ROCLAS machines undergo comprehensive testing at multiple stages of production, including laser beam quality analysis, motion system verification, and actual cutting tests on reference materials. This multi-layered quality assurance process guarantees that every machine leaving the factory meets the stringent 0.01mm accuracy specification.

The practical benefits of this exceptional precision are evident in various applications. For intricate parts requiring tight tolerances, such as medical components or electronic connectors, ROCLAS eliminates the need for secondary finishing operations. In industries like automotive and aerospace, where part consistency is critical, the machine's repeatability ensures flawless mating of components across production batches.

ROCLAS' commitment to precision extends beyond hardware specifications. The company provides comprehensive technical support to help customers optimize their processes for maximum accuracy. From recommending appropriate cutting parameters for specific materials to advising on maintenance schedules for critical components, ROCLAS' engineering team ensures that the machine continues to perform at peak precision throughout its operational lifespan.

For customers requiring further technical details or specific application solutions, ROCLAS' support team is readily available to provide customized consultations. Whether it's understanding how the machine maintains its accuracy during extended production runs or exploring special configurations for unique material requirements, the company's technical experts can offer in-depth explanations and tailored recommendations.

Previous: Safe, Fast & Automated Fiber Laser Cutting

Next:Not

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.