Let me begin by saying what makes Roclas different. We don't just sell machines - we provide complete cutting solutions tailored to your specific production needs. Whether you're working with metal sheets, tubes, or complex components, we have the right equipment to maximize your productivity.

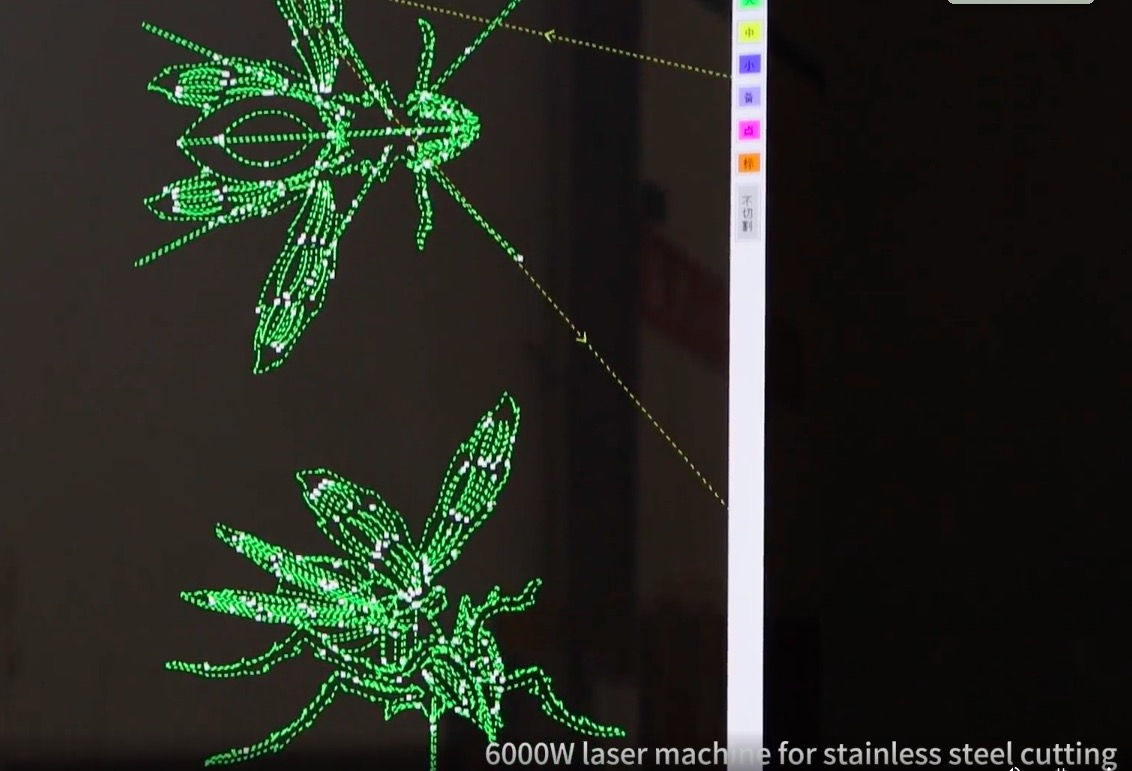

Our fiber laser cutting machines deliver exceptional performance through German-engineered technology. The heavy-duty steel construction provides unmatched stability during high-speed operation. You'll notice the difference immediately in the precision of every cut - we're talking about accuracy within ±0.03mm consistently. The cutting speed reaches up to 120m/min without compromising quality, while maintaining extremely narrow kerf widths to minimize material waste.

What really sets our machines apart is their remarkable energy efficiency. Compared to traditional CO2 lasers, our fiber technology consumes about 30% less power while delivering superior cutting capability. The maintenance is surprisingly simple too - no mirrors to align or complex optics to service. Just reliable, day-in-day-out performance with minimal downtime.

We offer several configurations to match your operation scale. Our compact desktop models are perfect for small workshops, while our industrial-grade systems handle continuous production in heavy manufacturing. The 5-axis models can process complex 3D contours in a single setup, eliminating multiple handling steps. For pipe cutting applications, our dedicated tube cutting lines deliver flawless results on round, square or rectangular tubing.

The environmental benefits are significant. With noise levels below 75dB and no hazardous gas emissions, our machines create a much better working environment than conventional alternatives. The solid-state laser source lasts over 100,000 hours - that's more than 10 years of maintenance-free operation.

But technology is only part of the story. Every Roclas machine comes with comprehensive training and local service support. Our engineers will work with your team to optimize cutting parameters for your specific materials. We provide lifetime technical consultation because we want your investment to keep paying dividends for years to come.

The return on investment is clear. Our customers typically see payback periods under 18 months through increased production capacity and dramatic reductions in operating costs. One automotive parts manufacturer increased their daily output by 40% while cutting energy bills by nearly half after switching to our system.

Let me show you some real-world examples. For a stainless steel kitchen equipment producer, we implemented a customized solution that reduced their material waste from 15% to just 3%. A metal furniture company doubled their production speed while achieving cleaner edges that eliminated secondary polishing. These aren't isolated cases - they represent the standard results our clients achieve daily.

We understand every business has unique challenges. That's why we offer free material testing at our demonstration center. Bring your sample parts and see firsthand how our lasers perform with your actual workpieces. Our application specialists will analyze your current process and recommend the most efficient solution.

The best way to appreciate Roclas' advantages is to see them in action. I'd like to invite you for a personal demonstration at our showroom or your facility. We can arrange to process your sample materials and provide detailed cutting data specific to your application. There's absolutely no obligation - just an opportunity to see what modern laser cutting technology can do for your operation.

To summarize, Roclas fiber laser cutting machines offer: German-engineered reliability, industry-leading precision, significant energy savings, minimal maintenance requirements, and comprehensive local support. Most importantly, they deliver measurable improvements to your bottom line through increased productivity and reduced operating costs.

I'd be happy to answer any questions you might have about how our solutions can address your specific cutting challenges. When would be a convenient time to discuss your requirements in more detail?

(This promotional article is not intended as a technical document. For product details, please consult the pre-sales engineer. We will serve you wholeheartedly. Your satisfaction is our continuous pursuit.)

Precedente:Roclas Fiber Laser Cutting Machines - Your Smart Solution for Precision Metal Processing

Prossimo:Non

Indipendentemente dal fatto che abbiate bisogno di una consulenza generale o di un supporto specifico, siamo lieti di aiutarvi.