Introduzione

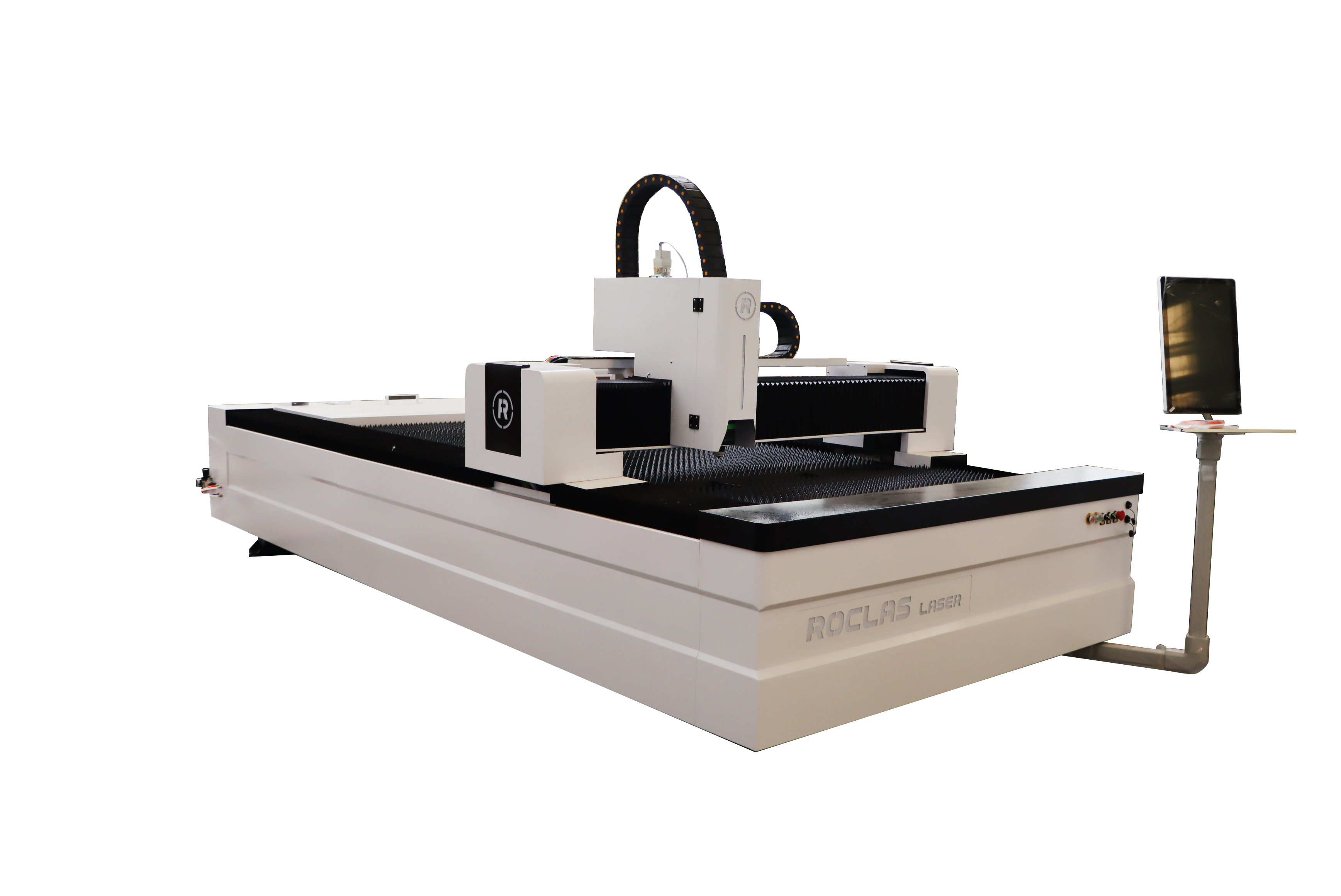

In the fast-evolving world of industrial manufacturing, laser cutting systems have become indispensable for achieving high precision, speed, and efficiency. Among the leading brands in this field, Roclas stands out with its cutting-edge laser cutting solutions designed to meet the demands of various industries. Whether for metal fabrication, automotive, aerospace, or electronics, Roclas laser cutting systems deliver unmatched performance, reliability, and cost-effectiveness.

Why Choose Roclas Laser Cutting Systems?

Roclas has built a reputation for excellence by integrating advanced technology with user-friendly designs. Here’s why businesses worldwide trust Roclas for their laser cutting needs

1. Superior Precision & Quality

Roclas laser cutting machines utilize high-powered fiber lasers that ensure clean, burr-free cuts with micron-level accuracy. This precision is crucial for industries requiring intricate designs and tight tolerances.

2. Prestazioni ad alta velocità

With optimized beam delivery and motion control systems, Roclas machines achieve faster cutting speeds without compromising quality. This boosts productivity, reducing lead times and operational costs.

3. Versatilità attraverso i materiali

Roclas laser cutting systems handle a wide range of materials, including stainless steel, aluminum, copper, brass, and even reflective metals. Their adaptability makes them ideal for diverse applications.

4. Energy Efficiency & Low Maintenance

Fiber laser technology consumes less power compared to CO₂ lasers, lowering energy costs. Additionally, Roclas machines are designed for minimal maintenance, ensuring long-term reliability.

5. Smart Automation & Software Integration

Roclas integrates intelligent automation features, such as automatic nozzle changing and real-time monitoring, enhancing workflow efficiency. Their user-friendly software allows seamless design-to-cut transitions.

Applications of Roclas Laser Cutting Systems

Le macchine da taglio laser Roclas sono ampiamente utilizzate in

- Automotive Industry – Precision cutting of chassis, body panels, and exhaust components.

- Aerospace & Defense – High-accuracy fabrication of turbine blades and structural parts.

- Electronics & Medical Devices – Micro-cutting for delicate components.

- Architecture & Metal Art – Customized designs for decorative and structural elements.

Conclusione

When it comes to laser cutting systems by Roclas, businesses gain a competitive edge through innovation, speed, and precision. Roclas continues to push the boundaries of laser technology, providing solutions that enhance productivity while reducing costs.

For manufacturers seeking reliable, high-performance laser cutting systems, Roclas remains the go-to choice. Explore their range today and experience the future of industrial cutting technology!

(Numero di parole 450)

Vuoi apportare modifiche o ulteriori dettagli? Posso espandere ulteriormente se necessario!

Indipendentemente dal fatto che abbiate bisogno di una consulenza generale o di un supporto specifico, siamo lieti di aiutarvi.