Yes, a fiber laser can cut metal—and it does so with exceptional precision, speed, and efficiency. Macchina di taglio laser a fibras have revolutionized metal fabrication, offering superior performance compared to traditional cutting methods like CO₂ lasers or plasma cutting.

How Does a Fiber Laser Cut Metal?

Fiber lasers generate a high-intensity beam of light through optical fibers doped with rare-earth elements such as ytterbium. This concentrated laser beam is directed onto the metal surface, melting or vaporizing the material with extreme accuracy. The process is controlled by CNC (Computer Numerical Control) systems, ensuring clean, repeatable cuts.

Key Advantages of Fiber Laser Cutting for Metal

1. High Precision & Clean Cuts

Fiber lasers produce extremely fine beams (as small as 0.1mm), allowing for intricate designs and sharp edges without burrs. This makes them ideal for industries requiring high accuracy, such as aerospace and electronics.

2. Faster Cutting Speeds

Compared to CO₂ lasers, fiber lasers cut metals like stainless steel, aluminum, and copper much faster—sometimes up to 5x quicker—boosting productivity.

3. Efficienza energetica

Fiber lasers convert nearly 50% of electrical power into usable laser energy, making them more efficient than CO₂ lasers (which typically achieve only 10-15% efficiency).

4. Low Maintenance & Long Lifespan

With no mirrors or moving parts in the laser source, fiber lasers require minimal maintenance. Their solid-state design ensures a long operational life (often exceeding 100,000 hours).

5. Versatility in Metal Cutting

Fiber lasers can cut a wide range of metals, including

- Stainless steel (up to 30mm thick)

- Aluminum (up to 20mm thick)

- Copper & brass (with proper wavelength adjustments)

- Mild steel (up to 25mm thick)

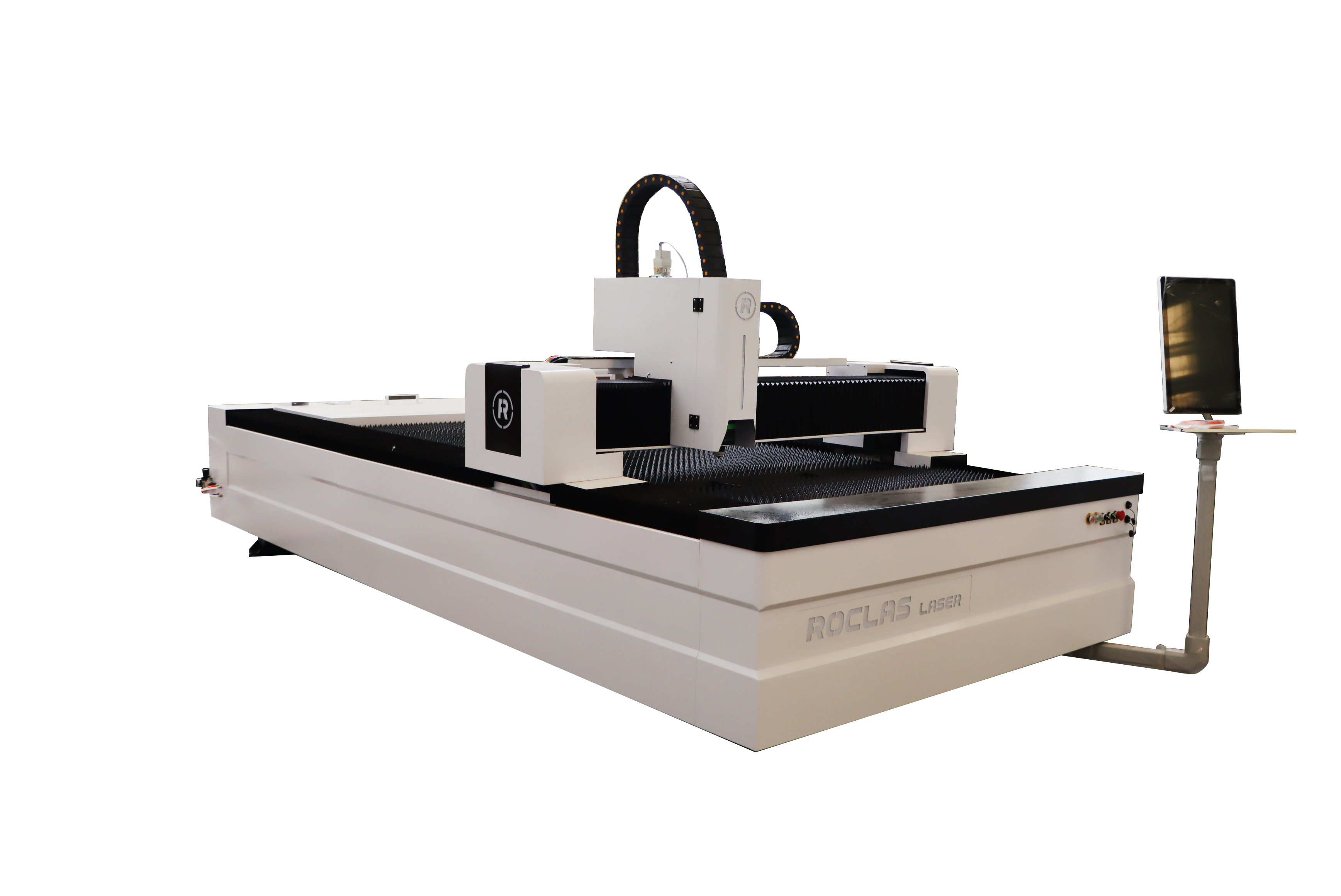

Perché scegliere Roclas Fiber Laser Cutting Machines?

At Roclas, we specialize in high-performance fiber laser cutting machines designed for industrial-grade metal fabrication. Our machines feature

- Controlli CNC avanzati per un funzionamento senza soluzioni di continuità

- High-power laser sources (1kW to 30kW+) for thick metal cutting

- Automatic nozzle changers for uninterrupted production

- Smart cooling systems to maintain optimal performance

Whether you're working with thin sheets or thick plates, Roclas fiber laser cutters deliver unmatched speed, precision, and reliability.

Conclusione

Fiber lasers are the go-to solution for modern metal cutting, offering speed, precision, and cost-effectiveness. If you're looking for a high-quality fiber laser cutting machine, Roclas provides industry-leading technology to meet your fabrication needs.

Upgrade your metal cutting process with Roclas today! 🚀

Indipendentemente dal fatto che abbiate bisogno di una consulenza generale o di un supporto specifico, siamo lieti di aiutarvi.