Introduzione

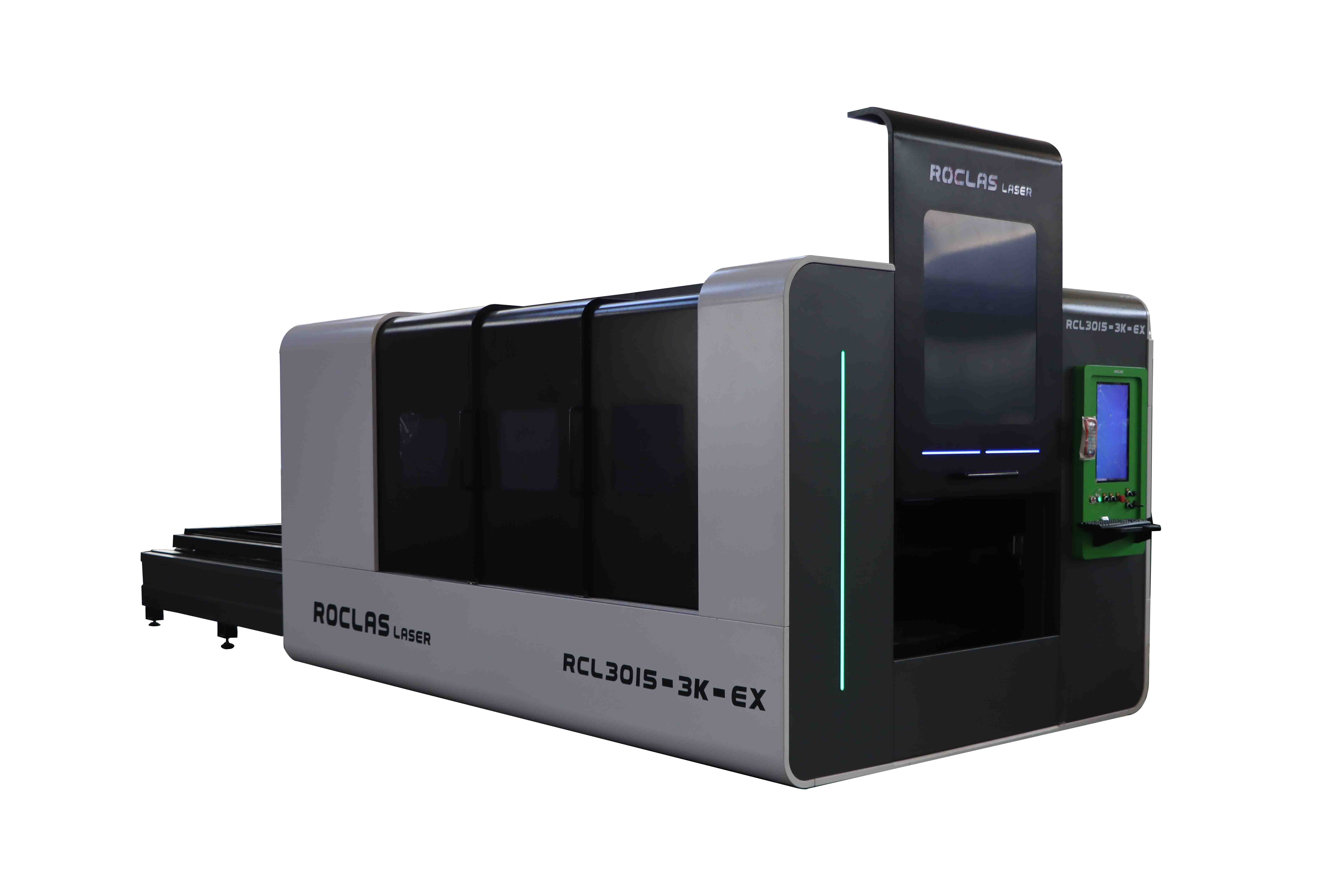

Laser cutout technology has revolutionized modern manufacturing, offering precision, speed, and versatility in cutting various materials. Whether for industrial fabrication, automotive parts, or intricate artistic designs, laser cutouts provide unmatched accuracy. Roclas, a leading brand in CNC engraving and laser cutting solutions, delivers high-performance fiber laser cutting machines that excel in producing flawless cutouts. In this guide, we explore the benefits, applications, and why Roclas stands out in the laser cutout industry.

---What is Laser Cutout?

Laser cutout refers to the process of using a high-powered laser beam to precisely cut or engrave materials such as metal, wood, acrylic, and more. Unlike traditional mechanical cutting, laser cutting is a non-contact method that ensures clean edges, minimal material waste, and high repeatability.

Roclas fiber laser cutting machines utilize advanced fiber laser technology, which is ideal for metal cutouts due to its high energy efficiency and superior beam quality.

---

Advantages of Laser Cutout with Roclas Machines

1. Precision & Clean Edges

- Roclas fiber lasers produce smooth, burr-free cuts with tolerances as tight as ±0.05mm, ensuring professional-grade results.

2. High-Speed Cutting

- With cutting speeds up to 100m/min, Roclas machines optimize productivity without compromising quality.

3. Versatility in Materials

- From stainless steel and aluminum to copper and brass, Roclas laser cutters handle a wide range of metals efficiently.

4. Low Maintenance & Energy Efficiency

- Fiber lasers consume less power compared to CO₂ lasers, reducing operational costs while maintaining high performance.

5. Automation & Smart Features

- Roclas machines support automatic feeding systems and AI-based optimization, streamlining production workflows.

---

Applications of Laser Cutout

- Industrial Manufacturing Precision parts for automotive, aerospace, and machinery.

- Signage & Advertising Custom metal signs, logos, and decorative panels.

- Jewelry & Art Intricate designs in precious metals with fine detailing.

- Electronics Precision-cut components for circuit boards and enclosures.

Roclas fiber laser cutting machines are engineered to meet diverse industry demands, ensuring reliability and efficiency.

---

Why Choose Roclas for Laser Cutout?

- Cutting-Edge Technology Roclas integrates the latest fiber laser advancements for superior performance.

- Durability & Longevity Built with high-quality components for extended machine life.

- Global Support & Training Comprehensive after-sales service and operator training programs.

- Custom Solutions Tailored laser cutting systems to fit specific production needs.

---

Conclusione

Laser cutout technology continues to shape modern manufacturing, and Roclas stands at the forefront with its high-precision fiber laser cutting machines. Whether for industrial applications or creative projects, Roclas delivers speed, accuracy, and reliability.

Upgrade your production with Roclas today—where innovation meets perfection in laser cutting!

---

Contaggio parole 520

Would you like additional details on specific Roclas models or material compatibility? Let us know how we can assist!

Indipendentemente dal fatto che abbiate bisogno di una consulenza generale o di un supporto specifico, siamo lieti di aiutarvi.